Page 85 - 理化检验-物理分册2024年第九期

P. 85

9

质量控制与失效分析 DOI:10.11973/lhjy-wl230126

导向臂疲劳寿命试验断裂原因

彭 霜,滕跃飞,金 一,孙智君

(中国航发商用航空发动机有限责任公司,上海 201306)

摘 要:在对某导向臂进行疲劳寿命试验时,其发生早期断裂问题。采用宏观观察、化学成分分

析、金相检验、硬度测试、扫描电镜分析等方法对导向臂断裂原因进行分析。结果表明:导向臂发生

了低周疲劳断裂,裂纹源区位于导向臂下表面,呈多源、线源特征,源区未见冶金缺陷与加工损伤;

导向臂表面存在脱碳层,脱碳层硬度偏低、抗疲劳能力下降是导向臂发生早期疲劳断裂的主要原因;

导向臂表面未形成有效的喷丸强化层,导致其疲劳强度降低,促进了导向臂发生断裂。

关键词: 导向臂;52CrMoV4钢;疲劳断裂;脱碳层;喷丸

中图分类号:TB31;TG115.2 文献标志码:B 文章编号:1001-4012(2024)09-0069-05

Cause of fracture in fatigue life test of guiding arm

PENG Shuang, TENG Yuefei, JIN Yi, SUN Zhijun

(AECC Commercial Aircraft Engine Co., Ltd., Shanghai 201306, China)

Abstract: During the fatigue life test of a certain guiding arm, early fracture occurred. The reasons for the

fracture of the guide arm were analyzed using macroscopic observation, chemical composition analysis, metallographic

examination, hardness testing, scanning electron microscopy analysis. The results show that the guiding arm experienced

low cycle fatigue fracture, with the source region located on the lower surface of the guiding arm, exhibiting multi-source

and line source characteristics. No metallurgical defects or processing damage were found in the source region. There

was a decarburization layer on the surface of the guide arm, and the low hardness and reduced fatigue resistance of the

decarburization layer were the main reasons for the early fatigue fracture of the guide arm. The surface of the guiding arm

did not form an effective shot peening layer, resulting in a decrease in its fatigue strength, which promoted the fracture

of the guiding arm.

Keywords: guiding arm; 52CrMoV4 steel; fatigue fracture; decarburization layer; shot peening

52CrMoV4钢属于Cr-V系弹簧钢,向钢中添加 热→双边轧制→弯头(加热) →卷耳(加热) →热处

Mo、V元素可以使其耐磨性增强、过热敏感性降低、 理(淬火+回火) →喷丸处理。某52CrMoV4钢导向

强度和韧性提高。该合金具有优良的力学性能,疲劳 臂在疲劳寿命试验过程中出现早期断裂现象,疲劳

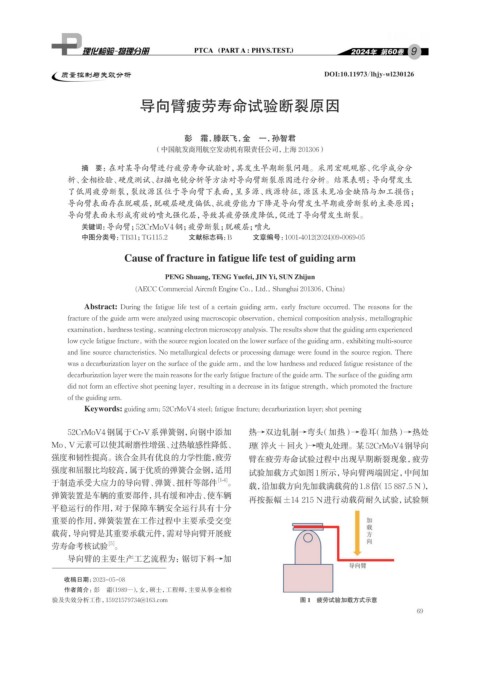

强度和屈服比均较高,属于优质的弹簧合金钢,适用 试验加载方式如图1所示,导向臂两端固定,中间加

于制造承受大应力的导向臂、弹簧、扭杆等部件 [1-4] 。

载,沿加载方向先加载满载荷的1.8倍(15 887.5 N),

弹簧装置是车辆的重要部件,具有缓和冲击、使车辆

再按振幅±14 215 N进行动载荷耐久试验,试验频

平稳运行的作用,对于保障车辆安全运行具有十分

重要的作用,弹簧装置在工作过程中主要承受交变

载荷,导向臂是其重要承载元件,需对导向臂开展疲

劳寿命考核试验 。

[5]

导向臂的主要生产工艺流程为:锯切下料→加

收稿日期:2023-05-08

作者简介:彭 霜(1989-) ,女,硕士,工程师,主要从事金相检

验及失效分析工作,15921579734@163.com 图 1 疲劳试验加载方式示意

69