Page 41 - 理化检验-物理分册2025年第四期

P. 41

高学敏,等:基于ABAQUS软件的螺栓连接疲劳行为及寿命预测

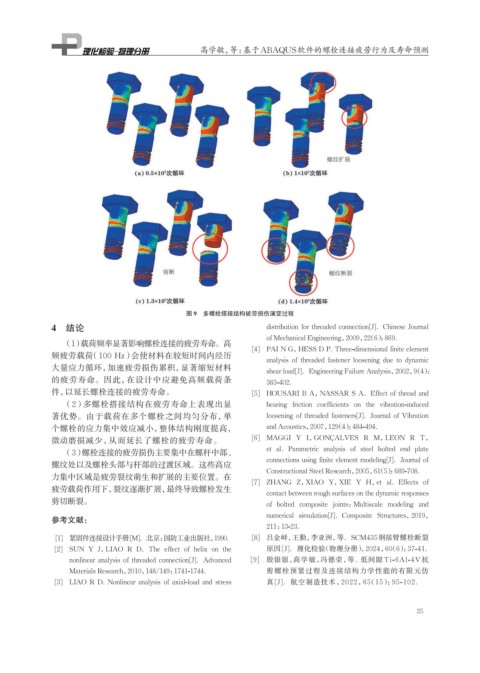

图 9 多螺栓搭接结构被劳损伤演变过程

4 结论 distribution for threaded connection[J].Chinese Journal

of Mechanical Engineering,2009,22(6):869.

(1)载荷频率显著影响螺栓连接的疲劳寿命。高

[4] PAI N G,HESS D P. Three-dimensional finite element

频疲劳载荷(100 Hz)会使材料在较短时间内经历

analysis of threaded fastener loosening due to dynamic

大量应力循环,加速疲劳损伤累积,显著缩短材料 shear load[J].Engineering Failure Analysis,2002,9(4):

的疲劳寿命。因此,在设计中应避免高频载荷条 383-402.

件,以延长螺栓连接的疲劳寿命。 [5] HOUSARI B A,NASSAR S A.Effect of thread and

(2) 多螺栓搭接结构在疲劳寿命上表现出显 bearing friction coefficients on the vibration-induced

著优势。由于载荷在多个螺栓之间均匀分布,单 loosening of threaded fasteners[J].Journal of Vibration

个螺栓的应力集中效应减小,整体结构刚度提高, and Acoustics,2007,129(4):484-494.

微动磨损减少,从而延长了螺栓的疲劳寿命。 [6] MAGGI Y I,GONÇALVES R M,LEON R T,

et al.Parametric analysis of steel bolted end plate

(3)螺栓连接的疲劳损伤主要集中在螺杆中部、

connections using finite element modeling[J].Journal of

螺纹处以及螺栓头部与杆部的过渡区域。这些高应

Constructional Steel Research,2005,61(5):689-708.

力集中区域是疲劳裂纹萌生和扩展的主要位置。在

[7] ZHANG Z,XIAO Y,XIE Y H,et al.Effects of

疲劳载荷作用下,裂纹逐渐扩展,最终导致螺栓发生

contact between rough surfaces on the dynamic responses

剪切断裂。 of bolted composite joints:Multiscale modeling and

numerical simulation[J].Composite Structures,2019,

参考文献:

211:13-23.

[1] 紧固件连接设计手册[M].北京:国防工业出版社,1990. [8] 吕金峄,王勤,李亚洲,等.SCM435钢摇臂螺栓断裂

[2] SUN Y J,LIAO R D.The effect of helix on the 原因 [J].理化检验(物理分册),2024,60(6):37-41.

nonlinear analysis of threaded connection[J].Advanced [9] 殷银银, 高学敏,冯德荣,等.低间隙 Ti-6Al-4V 抗

Materials Research,2010,148/149:1741-1744. 剪 螺栓预紧过程及连接结构力学性能的有限元仿

[3] LIAO R D. Nonlinear analysis of axial-load and stress 真 [J].航空制造技术,2022,65(15):95-102.

25