Page 83 - 理化检验-物理分册2024年第十一期

P. 83

11

质量控制与失效分析 DOI:10.11973/lhjy-wl230302

某高压断路器齿轮轴断齿原因

杜书万,李纪强,段永磊,李晓征,王海燕

(河南平高电气股份有限公司,平顶山 467000)

摘 要:某高压断路器在300次开合试验后动作异常,对其进行解体后发现一级齿轮轴发生断齿

现象。采用宏观观察、化学成分分析、硬度及渗碳层深度测试、金相检验、扫描电镜及能谱分析等方

法对齿轮轴断齿原因进行分析。结果表明:渗碳时温度及碳势偏高,导致组织中产生粗针状马氏体

和网状碳化物,使材料的脆性增大;齿轮轴在转动过程中,首先在齿根脆性相附近产生显微裂纹,在

应力作用下,裂纹沿晶界进一步扩展,最终导致齿轮轴发生沿晶断裂。

关键词: 齿轮轴;碳势;粗针状马氏体;网状碳化物;沿晶断裂

中图分类号:TG115.2;TB31 文献标志码:B 文章编号:1001-4012(2024)11-0067-04

Reason for gear shaft tooth breakage of a certain high-voltage circuit breaker

DU Shuwan, LI Jiqiang, DUAN Yonglei, LI Xiaozheng, WANG Haiyan

(Henan Pinggao Electric Co., Ltd., Pingdingshan 467000,China)

Abstract: A certain high-voltage circuit breaker operated abnormally after 300 opening and closing tests, and

upon disassembly, it was found that the first gear shaft had broken teeth. The reasons for gear shaft tooth breakage were

analyzed using macroscopic observation, chemical composition analysis, hardness and carburizing layer depth testing,

metallographic examination, scanning electron microscopy and energy spectrum analysis. The results show that during

carburizing, the temperature and carbon potential were too high, resulting in the formation of coarse needle like martensite

and network carbides in the microstructure, which increased the brittleness of the material. During the rotation of the gear

shaft, microcracks first appear near the brittle phase at the tooth root. Under stress, the cracks further propagate along

the grain boundaries, ultimately led to intergranular fracture of the gear shaft.

Keywords: gear shaft; carbon potential; coarse needle like martensite; net like carbide; intergranular fracture

高压断路器是电力系统的重要组成部分,其主 1 理化检验

要作用是开断、关合线路的正常电流和故障电流,以 1.1 宏观观察

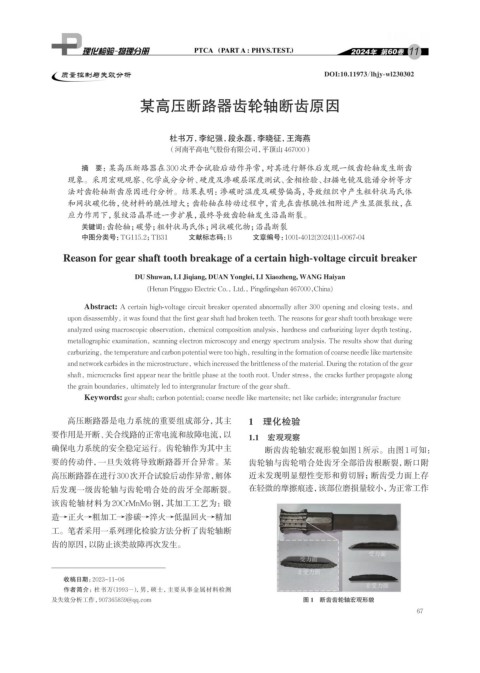

确保电力系统的安全稳定运行。齿轮轴作为其中主 断齿齿轮轴宏观形貌如图1所示。由图1可知:

要的传动件,一旦失效将导致断路器开合异常。某 齿轮轴与齿轮啃合处齿牙全部沿齿根断裂,断口附

高压断路器在进行300次开合试验后动作异常, 解体 近未发现明显塑性变形和剪切唇;断齿受力面上存

后发现一级齿轮轴与齿轮啃合处的齿牙全部断裂。 在轻微的摩擦痕迹,该部位磨损量较小,为正常工作

该齿轮轴材料为20CrMnMo钢,其加工工艺为:锻

造→正火→粗加工→渗碳→淬火→低温回火→精加

工。笔者采用一系列理化检验方法分析了齿轮轴断

齿的原因,以防止该类故障再次发生。

收稿日期:2023-11-06

作者简介:杜书万(1993-) ,男,硕士,主要从事金属材料检测

及失效分析工作,907365859@qq.com 图 1 断齿齿轮轴宏观形貌

67