Page 34 - 理化检验-物理分册2024年第十二期

P. 34

12

专题报道 DOI:10.11973/lhjy-wl240295

埋地输油管道焊接弯管开裂原因

金苏柯 ,罗婵媛 ,胡家喜 ,潘安霞 2

1

1

1

(1.江苏省特种设备安全监督检验研究院 常州分院,常州 213125;2.常州大学 机械与轨道交通学院,常州 213164)

摘 要:某城市埋地输油管道服役约10个月后,在焊接弯管处开裂并发生泄漏现象。采用宏观观

察、化学成分分析、扫描电镜分析、金相检验等方法对焊接弯管开裂的原因进行分析。结果表明:焊

接弯管选材不当,导致焊接后热影响区形成硬而脆的马氏体,马氏体对氢脆型开裂比较敏感;在服

役过程中,管道前侧排水系统泄漏导致下方基土被冲散,弯管下方无支撑,使该区域承受拉应力,焊

接弯管在拉应力的作用下,在焊接热影响区发生氢脆延迟性开裂。

关键词: 焊接;不锈钢;延迟性开裂;氢脆;拉应力

中图分类号:TB31;TG115.2 文献标志码:B 文章编号:1001-4012(2024)12-0018-03

Causes of cracking of welded elbow of buried oil pipeline

JIN Suke , LUO Chanyuan , HU Jiaxi , PAN Anxia 2

1

1

1

(1. Changzhou Branch, Special Equipment Safety Supervision Inspection Institute of Jiangsu Province, Changzhou 213125, China;

2. School of Mechanical and Rail Transportation, Changzhou University, Changzhou 213164, China)

Abstract: After about 10 months of service, a buried oil pipeline in a city cracked and leaked at the welded

elbow. The causes of cracking of welded elbow were analyzed by macroscopic observation, chemical composition

analysis, scanning electron microscope analysis and metallographic examination. The results show that the improper

material selection of welded elbow led to the formation of hard and brittle martensite in the heat affected zone after

welding. Martensite was sensitive to hydrogen embrittlement cracking. During the service process, the leakage

of the drainage system on the front side of the pipeline caused the lower foundation soil to be dispersed, and there

was no support under the elbow, resulting in tensile stress in this area. Under the action of tensile stress, hydrogen

embrittlement delayed cracking occurred in the welding heat affected zone of the welded elbow.

Keywords: welding; stainless steel; delayed cracking; hydrogen embrittlement; tensile stress

某城市埋地输油管道材料为25号钢,管道由无 次发生。

缝钢管和冲压弯头焊接而成,设计压力为0.6 MPa,

1 理化检验

规格为 273.1 mm×7.1 mm(长度×外径),弯头角

度为90°, 安装条件为R=5D (R为管线弯曲部分安 1.1 宏观观察

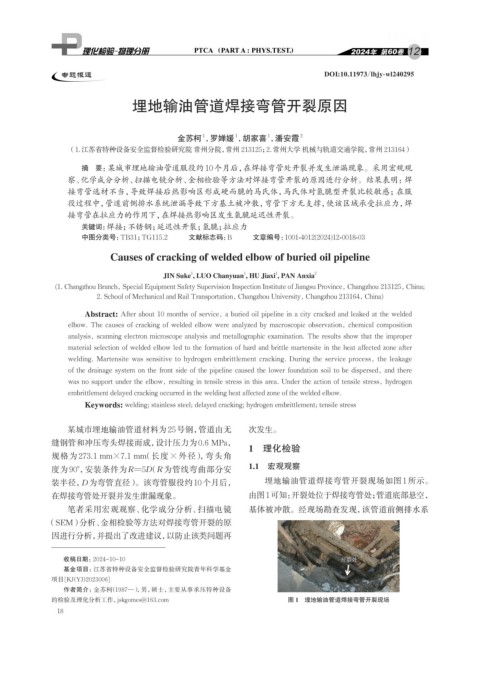

装半径, D为弯管直径)。该弯管服役约10个月后, 埋地输油管道焊接弯管开裂现场如图 1所示。

在焊接弯管处开裂并发生泄漏现象。 由图1可知: 开裂处位于焊接弯管处;管道底部悬空,

笔者采用宏观观察、化学成分分析、扫描电镜 基体被冲散。经现场勘查发现,该管道前侧排水系

(SEM)分析、金相检验等方法对焊接弯管开裂的原

因进行分析,并提出了改进建议,以防止该类问题再

收稿日期: 2024-10-10 开裂处

基金项目:江苏省特种设备安全监督检验研究院青年科学基金

项目[KJ(YJ)2023006]

作者简介:金苏柯(1987—),男,硕士,主要从事承压特种设备

的检验及理化分析工作,jskgomes@163.com 图 1 埋地输油管道焊接弯管开裂现场

18